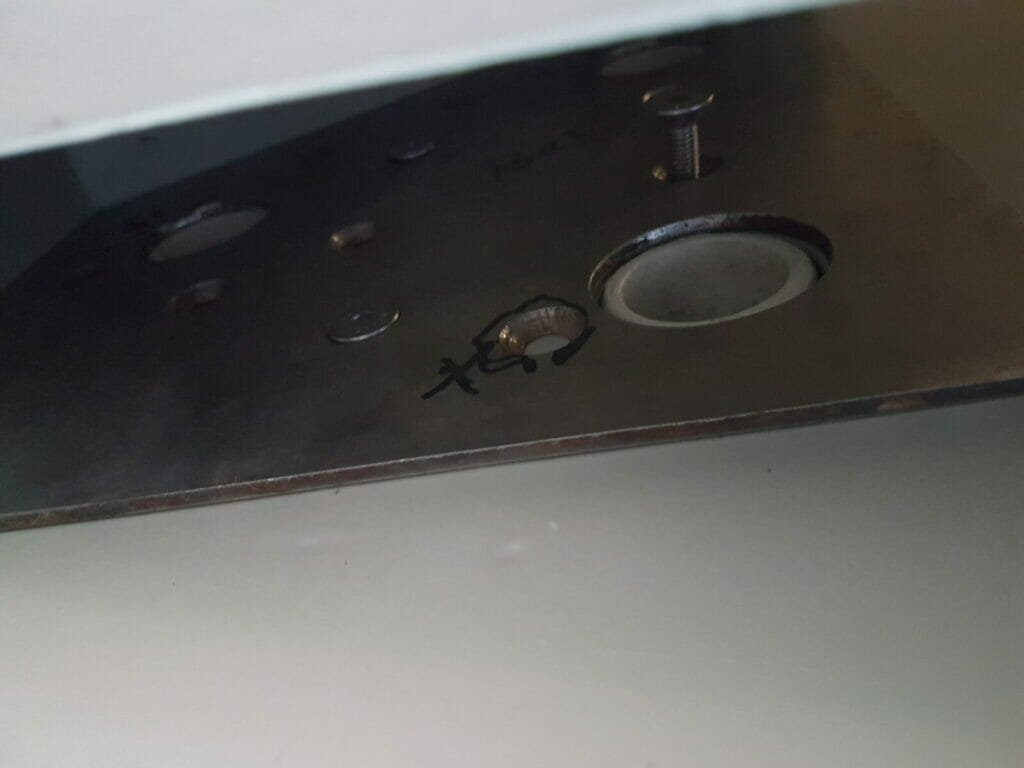

Have decided to fit the keel mechanism from Jack of London T4 as it was all made from stainless steel ,Problem is getting this lot to fit in the keel box as it has a 5mm plate that retains the 12x countersunk bolts as A5 had the bolts going straight in to wood which looks weak ..

It seems the blocks that locate the keel bolts to stop them spinning are hitting the outer case.. I put this all in place tonight and have decided to make some new bolt stops and shape them (rounded )to match the bit missing from the bolt end this will then be tig welded to clutch plate keeping it slim in profile ,this will fit just inside inspection holes.. I only need a couple of milimeters.

Simon,

As ever – perfection continues! I thought I’d seen the last of T4’s keel bolts – should have known better. All the stainless steel bits and pieces on T4 were the work of the owner prior to me. Being a supervisor at Sellafield, he obviously had access to the fabrication shop on site.

But I digress; your work on Diaphony is superb. But sooner or later, she’s going to have to get her bottom wet. The Uffa Fox event in Cowes would be tremendous. Only problem is that I’ll have to hide Atalanta awy in some obscure corner so as not to be shown up………….

Great stuff Simon – keep it up,

Mike

Epoxy primer undercoat ( EPU)

3x coats in succession allowing flash off between coats . Found this more painful to do than 3x races racing motocross.. doing that next week a Sunday off..

Great to see so much progress. She really is going to be fantastic when finished!

Looking forward to seeing her in Cowes this Summer 😉