- This topic has 8 replies, 4 voices, and was last updated 5 years, 1 month ago by .

- Topic

Hello guys, been a while but using the warm weather I have been at work doing what I can. she started as loose tape on the deck and a little hole in the transom as i bought her but has evolved to.

- 70% of the Transom had to be rebuilt. She is solid but needs finishing

- Roof in the back was rotten through, along with the main support, this was replaced but not shaped or trimmed so its about double the old ones thickness

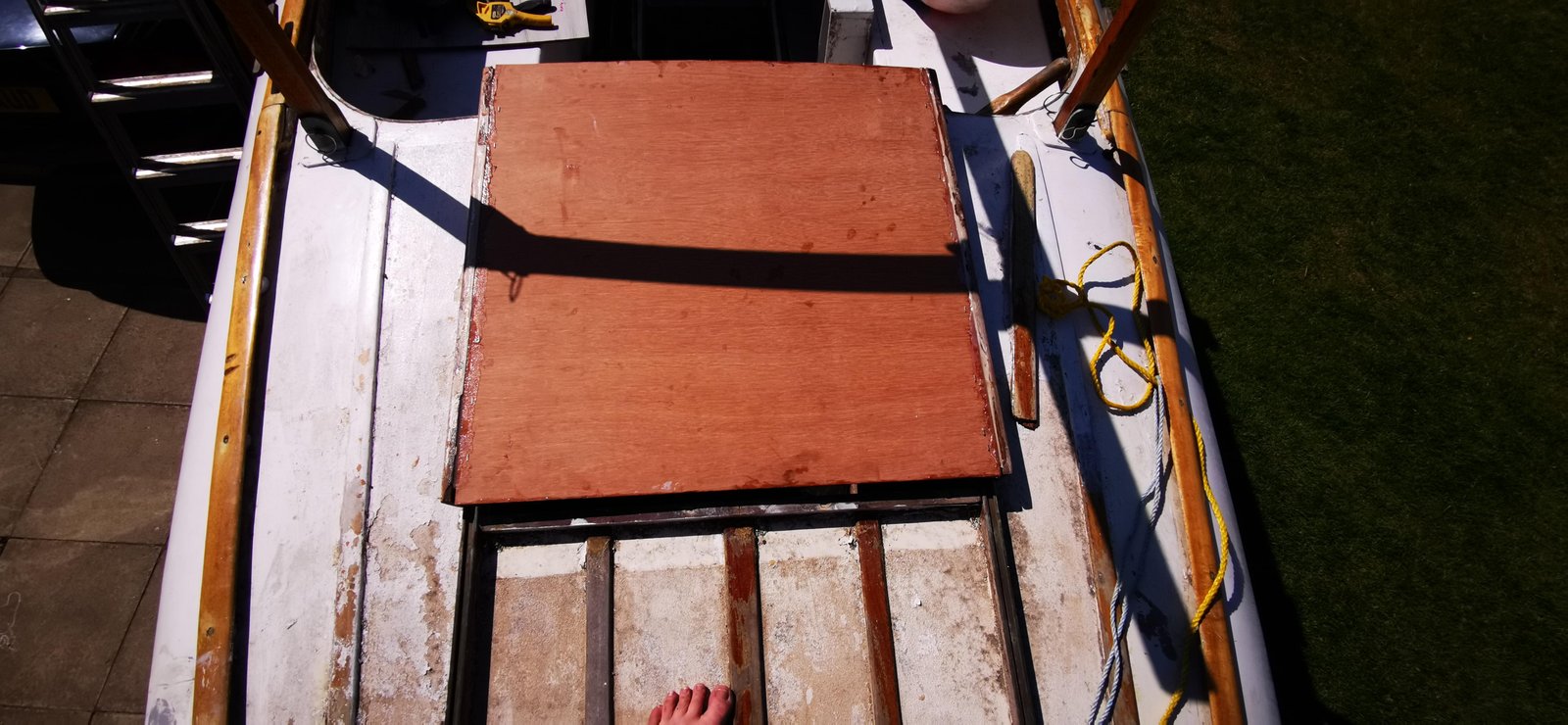

- Every hatch was rotten through. Rear hatch rebuilt but needs sanded and finished, Same with the front

- The entire deck was pretty much acting as a water tank between the veneers

- many holes in the hull. Mostly done filling and fixing

- Rot in the bubble, in the works, decided to take it back to wood and epoxy coat her

- Trailer is a mess with broken brakes and a bit of rot but we will patch and launch her then redo that

- The dolphin engine is turning smooth as silk after a lot of fear and a few weeks of 2 stroke oil and rocking with a big stick and a socket.

Its all a bit rough and ready right now and needs a lot of touch ups but she will hopefully sail this year. Below are some of my battles. Sure I made some mistakes but nothing that can not be restored later if someone had the funds. i plan to use her a lot so I am trying to make the repairs solid. The hatches will be adjusted colour wise when I varnish the epoxy with some mineral stains. hope you find it interesting

Stern

First 15 mm, she got 2 laminated with epoxy

Roof is ply because it is painted and the veneer I got was trash

Matchsticks and splinters aka the rear hatch

Matchsticks and splinters aka the rear hatch Remade, i then ground out old filler and used epoxy and wood flour to fill the gaps then epoxied the hatch to be varnished

Remade, i then ground out old filler and used epoxy and wood flour to fill the gaps then epoxied the hatch to be varnished Front hatch got fiberglass so I will have to sand and tweak the colour, using the old frame a 15mm ply

Front hatch got fiberglass so I will have to sand and tweak the colour, using the old frame a 15mm ply making a mess

making a mess Older patch before i got the wood flour using epoxy and thickners

Older patch before i got the wood flour using epoxy and thickners more holes

more holes

Checking the fit of the new hatch

I like the look of the ground areas filled with wood flour and epoxy

I like the look of the ground areas filled with wood flour and epoxy Cold forming the hatch

Cold forming the hatch Rot in the bubble, the smell was exactly like a forest floor so I pumped some acetone in before i cut away any more rot

Rot in the bubble, the smell was exactly like a forest floor so I pumped some acetone in before i cut away any more rot taking her back to all wood hatches and bubble, I think she looks much better now. The wood is in great shape other than the rotten bits. Will be rebuilt with Douglas fur and the bits of 2mm veneer I got that turned out to be of little use.

taking her back to all wood hatches and bubble, I think she looks much better now. The wood is in great shape other than the rotten bits. Will be rebuilt with Douglas fur and the bits of 2mm veneer I got that turned out to be of little use.

- You must be logged in to reply to this topic.

Matchsticks and splinters aka the rear hatch

Matchsticks and splinters aka the rear hatch Remade, i then ground out old filler and used epoxy and wood flour to fill the gaps then epoxied the hatch to be varnished

Remade, i then ground out old filler and used epoxy and wood flour to fill the gaps then epoxied the hatch to be varnished Front hatch got fiberglass so I will have to sand and tweak the colour, using the old frame a 15mm ply

Front hatch got fiberglass so I will have to sand and tweak the colour, using the old frame a 15mm ply making a mess

making a mess Older patch before i got the wood flour using epoxy and thickners

Older patch before i got the wood flour using epoxy and thickners more holes

more holes

I like the look of the ground areas filled with wood flour and epoxy

I like the look of the ground areas filled with wood flour and epoxy Cold forming the hatch

Cold forming the hatch Rot in the bubble, the smell was exactly like a forest floor so I pumped some acetone in before i cut away any more rot

Rot in the bubble, the smell was exactly like a forest floor so I pumped some acetone in before i cut away any more rot taking her back to all wood hatches and bubble, I think she looks much better now. The wood is in great shape other than the rotten bits. Will be rebuilt with Douglas fur and the bits of 2mm veneer I got that turned out to be of little use.

taking her back to all wood hatches and bubble, I think she looks much better now. The wood is in great shape other than the rotten bits. Will be rebuilt with Douglas fur and the bits of 2mm veneer I got that turned out to be of little use.

my Failed attempt

my Failed attempt old mans one

old mans one