- This topic has 1 reply, 2 voices, and was last updated 5 years, 3 months ago by .

- Topic

Martin Bennett has provided some great input into the replacement of keel bolts. His ideas for keeping grease in the working area can also be applied to existing keel bolts. At the 2020 AGM Martin brought along examples of his ideas which are outlined below under three headings:

- Making a new bolt

- Drilling bolts to keep grease on the pivot

- Guides to refit the bolt

Martin has used all of these ideas on his own and many other Atalantas, so they are well proven.

1. Making a new bolt

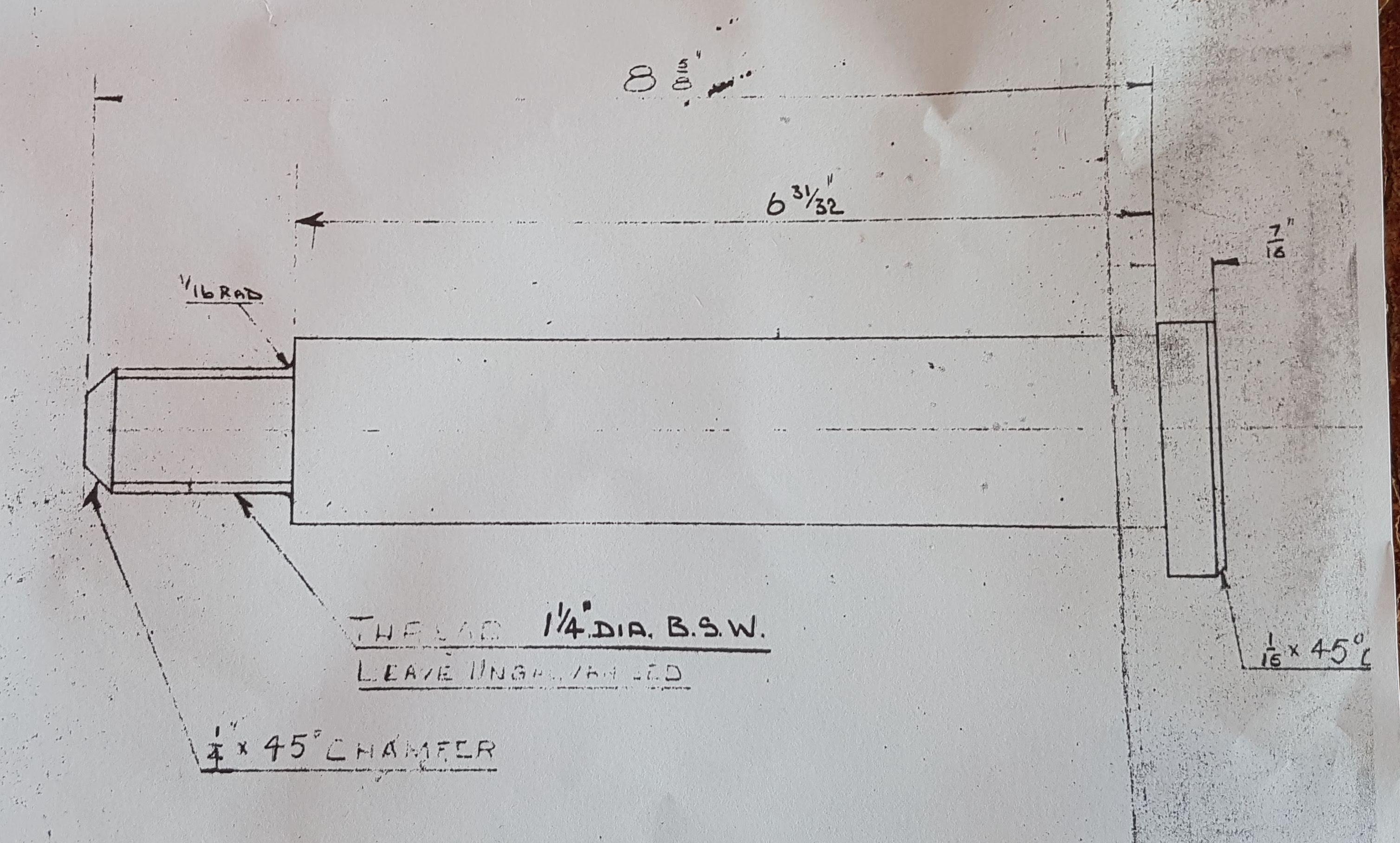

These are the dimensions of a bolt:

When making new bolts they are often turned on a lathe from large diameter stock down to the required 1.5″. This is costly in material and time-consuming in machining.

For around just £8 GKN can supply 8:8 grade High Tensile steel bolt blanks with accurate 1.5″ outside diameters. The only machining required on these is to round off the bolt head and cut the flat and then to put the thread on the end.

2. Drill bolts to keep grease on the pivot

For the main pivolt bolt (the one at the bottom) Martin then recommends drilling the bolts down their length radially, and maching annualr rings as in the picture above. This provides a route for grease – the keel bolt ‘nut’ is filled with grease and screwed on, forcing grease down the axial hole and out through the radial holes and then around the bolt in the annual grooves. Martin also puts a thread in the end of the axial hole so that a grease nipple can be fitted for initial priming and then removed.

3. Guides to assist in refitting the bolts

Martin has made guides to assist in refitting keel bolts. These aluminium ferrules are placed over the end ot the bolt before it is offered up. The chamfer on the ferrule adjusts the position of the keel as the bolt is driven in with a hammer. This can save an hour of trial and error attempting to line up the keel hole with those on the boat.

The groove in the ferrule assists in bolt alignment. When it can be seen sticking out of the bolt tube the flat on the keel bolt head is correctly aligned with the lug on the keel clamp plate.

Martin Bennet is happy to provide these for any owners who want them – contact Martin direct or through the contact form at the foot of this page.

- You must be logged in to reply to this topic.