- This topic has 2 replies, 2 voices, and was last updated 5 years, 1 month ago by .

-

Topic

-

Hello again

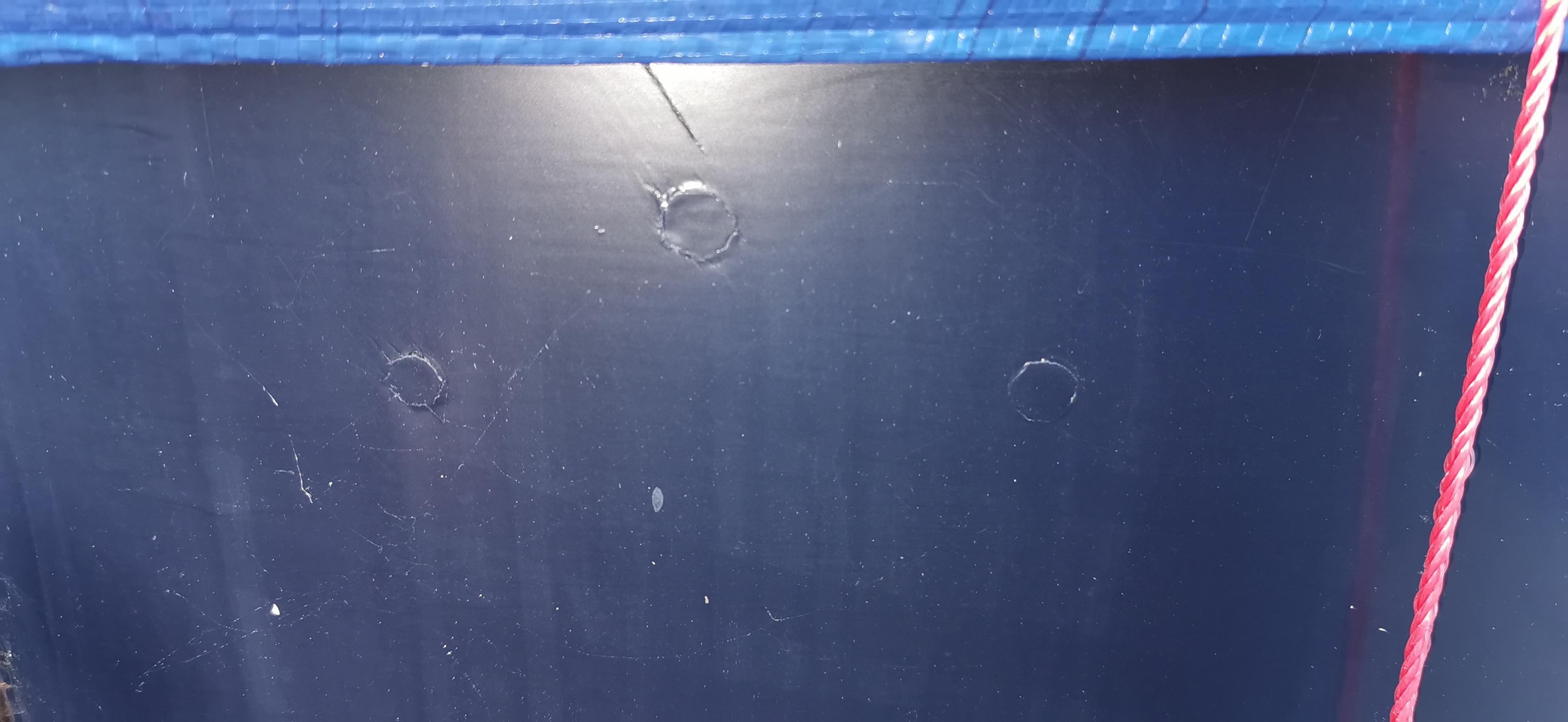

I am a few days away from digging into the repair of the of Blue jackaroo and noticed some bubbles under the paint of her hull.

I am not sure if these are part of the normal hull? or what they are doing at all to be honest. the corrosion looks a little odd to me.

In any event what would be the best way to go about sorting this? I am considering treating them with something to harden the corrosion then epoxying over them but i am a complete novice so i am not sure. the wood looks fine other than the gouging.

The paint is raised on all of them I assume because of the corrosion I just picked away at this one to see what was going on because I feared rot was under each of them.

Any help would be greatly appreciated

Fraser

- You must be logged in to reply to this topic.