Forum Replies Created

- AuthorReplies

Chris GreenParticipant

Chris GreenParticipantHello Stephen

Firstly, your inboard should provide more than enough oomph to push your Atalanta along – even against an ebb tide. You might consider checking your motor setup. If this is for A89, as I recall she was originally based on a lake and had a hydraulic drive – and is still the case, you may consider switching to a direct drive to add about 25% more power.

On the outboard options, many Atalantas have had outboard motor installations – including my current one (A169) when I originally acquired her in 2011. The outboard had a complete wired setup with ignition and morse controls routed to cockpit. I removed the installation as part of a total refit/rebuild – there are some archive photos of her with this setup in one of the back issues of the Annual Bulletin (also other Atalanta outboard setups as well. I have now a Lynch 48V 7.5 kW electric inboard motor. For any extended motoring I also carry an old (refurbed) Seagull SP 5hp outboard motor with a Seagull removable outboard bracket – from Sheridan Marine – with a long range tank. Some early Atalantas used the same long-shaft big prop Seagull engine instead of an inboard; one interesting article is in an early bulletin issue has the motor mounted on an outboard bracket outside the cockpit.

This link shows my transom outboard bracket holder installation i.e. for the seagull bracket bolted through to an internal 20mm hardwood backing plate

https://drive.google.com/file/d/1jISSTqvX3o8P04Vs3yTGdfE-5-7jaCce/view?usp=drivesdk

I hope all this is of some help.

Chris

Chris GreenParticipant

Chris GreenParticipantOxidisation of the original bronze screws around the keel boxes seems to be the issue in the photo. Over time the whole screw can degrade and allow moisture ingress. If it is just the heads of screws, they can be cleaned and a coat of varnish, epoxy or paint – polyurethane or two-pack etc will prevent further deterioration. It would be prudent to check the screws by extracting some of them. If replacing oxidised screws, it would also be prudent to seal the holes with epoxy as the plywood may have degraded around the oxidised screws. This is a maintenance issue to keep an eye on and affects the hull fixings as well.

I hope this helps

Chris

18/04/2023 at 14:14 in reply to: Sweet Sue A138: Progress report and Aft Cabin bunks – a rethink #26578 Chris GreenParticipant

Chris GreenParticipantHi Ryan

Congratulations on the refit progress.

Members have carried out various modifications to make better use the large aft cabin area. I have revamped the aft cabin on Elle to provide a double athwart bunk and other modifications. Had the same layout on Atalanta “Jaunty” which worked well. The full Elle refit (including aft cabin work) can be accessed under A169 blogs – found by selecting the Atalanta register link from the “Register” link on top menu bar. In the Atalanta register under A100 you can also access the Sailing Today review of Jaunty which shows the aft cabin modification. NB: Since posting the A169 refit blogs, have also added a holding tank.

I hope this is helpful.

Chris

Chris GreenParticipant

Chris GreenParticipantHello Trefor – There are plenty of rebuild examples for hull repairs on AOA – if you try a search with key words you should find plenty. Repairing damaged, delaminated or rotted with Agba veneers is fairly straightforward. A1 restoration of hull veneers by Mike Dixon post has a comprehensive step by step on hull repairs.

Chris

Chris GreenParticipant

Chris GreenParticipantI like the internal 3 point lifting harness arrangement for all the reasons mentioned by David. For any unfamiliar with the arrangement – the two front slings attach to the eyes either side of the main bulkhead and the longer third sling providing stability attaches to the eye on the keelson in the aft cabin. When planning to make a harness for Elle (A169) had initially planned to make a chain harness and Richard who uses this arrangement for launching / recovering A89 gave me the specification. My intention was to keep the harness on board, so for weight and convenience eventually opted for webbing slings. The supplier advised on technical specification required for the intended purpose. Each sling is rated a 2 tons, so comfortably over-engineered; heavy-duty lifting shackles complete the arrangement.

For any members interested…

The sizes and specification – T6973 – 3 slings

2T – 13FT 5″ WEBSLING x 1 (rear); 2T 10FT WEBSLINGS x 2 (front)

The supplier used was:

SECUREFIX DIRECT LTD PO BOX 6839, DUDLEY, DY1 9JJ TEAM@SECUREFIXDIRECT.COM http://WWW.SECUREFIXDIRECT.COM

Chris GreenParticipant

Chris GreenParticipantHi Doug And Nick)

I have replied twice to this thread, with links to canvas covers for Mary and A169, but nothing has loaded – perhaps there is a problem with the site.

Hopefully someone will see this one.

Chris

Chris GreenParticipant

Chris GreenParticipantThis article by Richard Hall (with photos) is quite useful and has other tips on handling the mast.

https://drive.google.com/file/d/1nI5ur0ami89ryTRwADjFwVcXFsArsqd4/view?usp=sharing

Chris GreenParticipant

Chris GreenParticipantJonathan – when using the standard Atalanta trailer for launching (the method I have used): if possible, back the trailer onto the slipway as far as you can at low water – uncouple from vehicle which is moved out of the tidal range; connect a hefty strop from trailer to tow bar for recovery. Then just wait for the tide to carry her off. NB: Essential to secure the wooden chocks onto the trailer – have had one float off under the boat before – very embarrassing! One other point is docking arms on the trailer are very useful for recovery – can be managed without, but boat not always perfectly aligned.

Chris GreenParticipant

Chris GreenParticipantHello Stephen

Just to add a little more on the boom height and aft head location:

Boom height – possibly fit a sliding gooseneck so you can raise the boom height when deploying Bimini – see my post A169 last year as part of the mast rebuild.

Aft cabin toilet:

I know of 3 aft cabin loos including my current arrangement – installation of this is described with photos in a previous post for A169 and in a bulletin; also had this arrangement on A100 – you can read the Sailing Today magazine article, (under A100) which has photos and commentary on the setup. Personally, I find the location far better than the fore peak arrangement.

Chris GreenParticipant

Chris GreenParticipantHi Stephan

The resources of the AOA website are very useful containing experience of members from Bulletin records; technical plans and ideas etc to help with your plans. I have been refitting (rebuilding!) A169 over a number of years – previously owned A 100 – here are some thoughts on my own experience of some of your proposed mod’s;

Holding tanks – to comply with various EU and local laws

Location below cockpit seat is my preference – This is made easier if the head is relocated to aft cabin as in A100 (Jaunty) and A169 (Elle); a pump-out/extract can be fitted into the top for emptying using marina suction hose etc. A simple valve arrangement allows switching between direct outlet and holding tank. Flexible or rigid tanks are available if you shop around – or possibly make your own from epoxy coated ply. If keeping the heads in fo’c’sle – a tank could be made to fit the area, but space would be a possible issue.

Bimini – possibly needing raising the goose neck to give sufficient headroom

See my post last year on fitting the cockpit tent and rebuilding the mast with a sliding goose neck fitting.

Rejigging the pushpit to incorporate a swimming ladder, a platform for stern-to mooring

Adding a frame/arch to support solar panelling, most likely added to the pushpit

Installing some form of bowsprit incorporating anchor guide, bow roller, tack point for a code 0/1.

Adding an electric windlass – principally to aid stern-to mooring single-handed with the aid of an anchor.

Fitting boom roller reefing – means reefing and sail management can be controlled from the cockpitNot sure that adding a “sugar scoop” arrangement around the transom mounted lifting rudder is feesible; transom mounted bathing / boarding ladders are fitted by many owners – I have a folding stainless steel version on A169 (and previously on A 100). The fore-deck arrangements are possible, if you were determined to incorporate them, but would add considerable clutter for fairly light ground tackle; similarly, the cockpit arch would also be adding windage and clutter for the proposed stern-to mooring maneuvers, bearing in mind that Atalantas are light displacement.

Tailored storage points for the rib/dinky on the rear deck – but this would impact access via the rear platform – is the idea of a foldable dinghy (a la Seahopper) a sensible option?

Aft deck was designed to carry a tender and also doubles as extra aft cabin headroom with the hatch open. I have a modified Seahopper as a tender and have seen at least one other Atalanta with a Seahopper on the aft deck. I would say a perfect choice for the Atalanta. Can be stored folded along the pushpit rail/ when not required.

Autohelm versus mechanical self steering gear. Eg Navico TP1800 Tillerpilot?If you mean wind vane versus electric tiller pilot/auto helm – both forms have been successfully used on Atalantas – have a look through the back editions of bulletins. Personally, I have used a number of tiller (and wheel) pilots on different boats over the years; a Simrad TP10 was the last one I used, which was perfectly adequate for an Atalanta. There was a forum discussion on mechanical wind-vanes which you could probably find -or why no start a new wind-vane topic. I know that a previous owner of A169 had one fitted back in the 70s. Another thought is self steering from the sheets with surgical bungee cord through the whipstaff / tiller. A number of these set-ups on youtube – here is a link (URL) to one:

https://www.youtube.com/watch?v=zHpyvxeK2I4

Installing an ice box with a cooling powered by the solar panelling

I have 2 x 1000V flexible roll-up panels on A169 deployed over the cockpit tent (there was a post on this); these provide sufficient charge for a bank of batteries for the 48V – 8kw electric motor; also have an aft mounted wind 200W wind charger (also a post on this installation). This level of charge maintains the battery bank. Not sure you would be able to run a fridge cooler from solar alone – would depend on the cool-box capacity etc.

Adding extra portlights or hatches to increase airflow and natural lighting in fore and rear cabins.

A straightforward job – worth checking on the AOA forum for salvage Atalanta portlights, but these can be fabricated; At least one Atalanta has fitted a standard (i.e. opening type) porthole through the transom.

Replacement inboard motor required – suitable power rating and make which would be easy to maintain in France/the med.

Various approaches to inboard auxiliary motors have been tried by owners over the years – suggest have a look through the back issues of the annual bulletin. It largely depends on what uses you are planning – long motoring stints across the channel in calm weather, or just getting in and out of harbour/berths etc.

230v shore power with distribution MCB board.

Straightforward matter – choose the siting of the shore supply inlet; run the 240V mains lead to an on board breaker switch and fused distribution panel.

NB: You can look up my posts covering refit issues noted above under A169 in the AOA Register (from the tab on the top menu bar (above).

A169 https://atalantaowners.org/boat-sn/a169/

I hope this is helpful Stephan.

Chris

Chris GreenParticipant

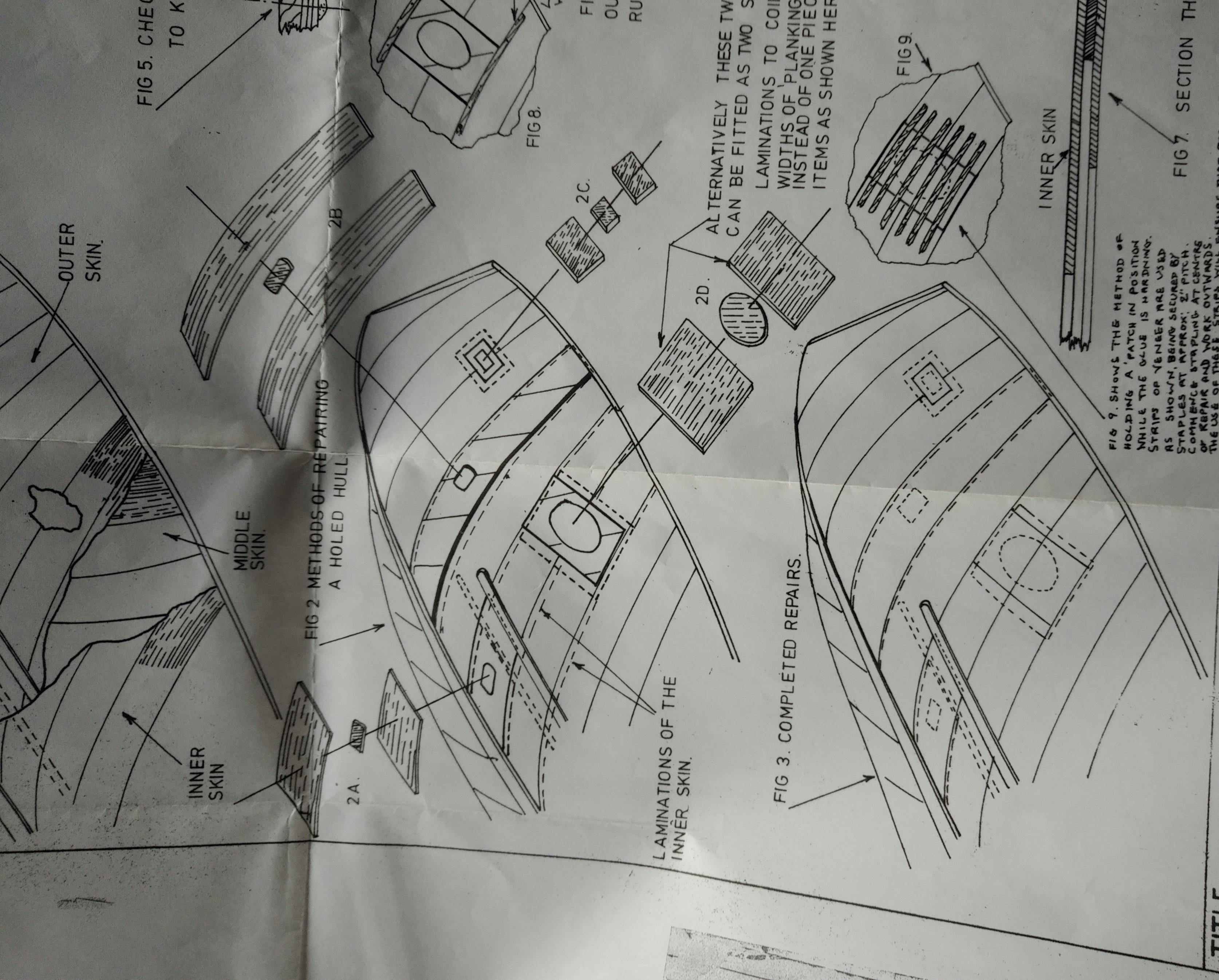

Chris GreenParticipantSome of the message disappeared at the end – should say – the Fairey drawing extracts relate to repairs on moulded dinghies – but still hold good for Atalanta repairs.

Chris

Chris GreenParticipant

Chris GreenParticipantHi Fraser

The repair can be carried out by laminating a veneer patch. The steps are quite straightforward – 1) Cut out the rotted area leaving a clean hole with sound structure around; 2) remove the outer and inner veneers back from the edge of the hole – i.e. outside and inside the coachroof leaving a step around the hole (shape can be square or oval): cut a central patch of agba veneer to fit the central hole and two outer agba veneer sections overlaying either side of the hole – about 50mm overlap should be okay.

Mix epoxy -I use Gurit SP106, but West System 105 /205 does the same job – either should be mixed with a filler/glue powder such as West 404 or 405 to thicken the epoxy. The final repair can be stapled and/or compressed to hold the repair in place. When finish sanded, the repair will be okay for final coat.

There is a Fairey guide on this Drawing B 12388 which is specifically for the moulded din

Best of luck

Chris GreenParticipant

Chris GreenParticipanthttps://www.scotsman.com/news/obituaries/obituary-barbara-calder-pioneering-yachtswoman-1-4712758

Fascinating to read about this lady; link (above) to her obituary in The Scotsman – very comprehensive.

Chris GreenParticipant

Chris GreenParticipantHi again Jonathan – just been thinking about it and remember that the metal sleeve was particularly difficult to remove from the shaft. Recall using an oversized wrench; engineer’s vice and heat application to the sleeve to free it off from the shaft.

Chris GreenParticipant

Chris GreenParticipantHello Jonathan

You have probably inspected everything already, but have attached a photo of the dismantled assembly from A169 – dismantled as part of the rebuild. Anyway – an odd thing to happen.

Hope you get it sorted soon.

Chris

Chris GreenParticipant

Chris GreenParticipantThe hull speed (c6.5 kt) is relatively high in the Atalanta compared with similar sized displacement cruisers due to the long waterline (c24.5). This in itself makes her faster in a decent blow than many larger displacement yachts with less waterline length and/more wetted area. Reducing weight will increase acceleration up to to hull speed, as will fairing and smoothing anything below the WL. Even though she is already light at 2t (depending on payload etc), it would take much further reduction in ballast (and hull modification) to achieve any chance of true planing – as opposed to surfing and slipping down waves etc.

As mentioned way back in this thread (citing UF’s book “Sailing Boats”), the Fairey built Uffa Fox designed 24 ft “Fairey Fox” (displacement 680 kilos) was a planing design with a superficial similarity to the Atalanta with a waterline of 24ft. This design could achieved planing with a hull form specifically designed with a long flat run with a chine aft; the flat run began about one third back from the bow. She had only an 85lb drop keel (3/8″ thick) with sharpened leading edge. The drop keel was so narrow it avoided the need for a rubber strip over the slot. So roughly scaling that up to the Atalanta – maybe 50lb per narrow keel! The Fairy Fox also required a crew to provide ballast as on any performance boat – Uffa warns that she should never be taken out with less than four people because of the windage in her topside mast and rigging.

Chris GreenParticipant

Chris GreenParticipantTrevor – Have attached below a picture of Kerry Piper in the 1970s sent by Sebastien Vanblaere (whose father was the owner in that period). Kerry Piper is sporting a wind vane of some type, so presumably worked okay. I picked up a

Plastimo vane system at one time (looks similar to the QME); it was too lightweight for the 9 ton Hilliard I wanted it for so I sold it to a chap with a smaller wooden (long keel) sloop and I think he had it working OK. I am looking at self steering from the sheets to tiller (whipstaff in this case) as an experiment when KP is afloat. Some interesting stuff on this if you are interested at http://www.blueanarchy.org/selfsteering/ – I think this could work on the Atalanta. Chris GreenParticipant

Chris GreenParticipantI concur with above – would just add a backing plate of 12 – 18 mm ply or hardwood epoxied to interior. NB: Original bronze sea cocks can usually be refurbished, but if replacing use marine version not the plumbing valve type.

Chris GreenParticipant

Chris GreenParticipantHello Jon – Welcome to the AOA. A check through the AOA registered owners yearbook indicates the nearest Atalanta 26 are in NZ – A87 Methusela (Murray Reid) and A123 (Bruce Davidson) . These are of course known / registered Atalantas; some have dropped from the radar (mostly in the US).

Chris GreenParticipant

Chris GreenParticipantI just managed to find an extract of the original PBO FF review from Dec 1998. The actual reference to 10 kt was anecdotal from the owner “while sliding down a wave in similar conditions under spinnaker”. So that is pretty qualified and obviously not bestowing general planing ability on the Fisherman.

Chris GreenParticipant

Chris GreenParticipantVery qualified though. The Fisherman article was a test sail in either – YM, PBO or ST. It was clocking 10 kt under sail in a blow, (to the surprise of the journalist), so planing/surfing down waves, but exceeding hull speed in any event. I seem to recall that the owner was also a racing yachtsman who used the FF for family sailing. The underwater profile is rounder and flatter than a normal displacement motor sailor, so I suppose there is less grip on the water.

Chris GreenParticipant

Chris GreenParticipantAs I recall the Atalanta had an annual group entry in the Round the Island in days of yore. Uffa Fox does not specifically mention the Atalanta with regard to planing in his published books on the subject. The lifting keel Fairy Fox 24, a beam of 6ft 3″ diplacement 1500lb and a sigle 6ft drop keel (of 65lb!!) designed with downwind planing in mind and to be sailed with a minimum crew of 4 (due to windage). Uffa in his book “Sailing Boats” has her recorded at 16kts. An Atalanta (I think A77) is featured in the 1963 “Uffa Fox Book of Sailing” , but no specific reference to planing. I remember an article in one of the sailing mags some years ago with a Fairey Fisherman on test planing downwind (I think under spinnaker) at 10kt!- surely the Atalanta could do at least as well. I’m sure other members have experienced surfing in displacement boats and the Atalanta has genuine ULDB credentials so one would suppose could be achieve planing given suitable rig set-up and conditions.

Chris GreenParticipant

Chris GreenParticipantHave used DEKS OLJE on and off over the years with pretty good results on various wooden boats. Two types D1 saturating and D2 gloss varnish.

Chris GreenParticipant

Chris GreenParticipantOK Trevor

Chris GreenParticipant

Chris GreenParticipantHi Trevor. Will try to put something together for the KP work to date. Do you have any format requirements (pdf or Word), word count etc? Cheers, Chris

Chris GreenParticipant

Chris GreenParticipantHello Jim – The Atalanta has a lifting keel arrangement with a pivot bush at the top of each plate. The Fisherman has a more conventional keel arrangement, so should be fastened with bolts through the hull in the usual manner. Chris

Chris GreenParticipant

Chris GreenParticipantI recently dismantled the whipstaff bearing assembly for Kerry Piper and had the same problem. I ended up taking it to a local engineering workshop where they managed to sweat it off!

Chris GreenParticipant

Chris GreenParticipant Chris GreenParticipant

Chris GreenParticipant Chris GreenParticipant

Chris GreenParticipantPicking her up next weekend – back to a local yard in Rye. She needs major work to hull and deck laminates above the WL; rebuild of cockpit and attention to keel boxes. Has a great refurbished original Atalanta trailer which is a bonus. Aim to put her under a plastic structure and hope to rig a scaffold lift (similar to the arrangement on Joanne, but free standing). Will be on the market for any decent salvaged trim – odds and ends WHY etc. A couple of port lights would be handy and will need a set of keel rubbers at some point. The final thing will be an engine – thinking of going down the hydraulic drive route. Will post pictures of work carried out on the AOA site as the project progresses. Probably looking at launching next spring – as “Kerry Piper” (if that was her original name. Cheers for now, Chris

- AuthorReplies