Forum Replies Created

- AuthorReplies

- 25/09/2020 at 22:58 in reply to: Reference in Yachting Monthly to Brian Black sailing an Atalanta #22250

NickKeymaster

NickKeymasterJonathan

Thanks for bringing this to our attention. A very sad accident. The Yachting Monthly website has an online article with some details. From the Registers Brian owned A78 Marianda in 1975.

Cheers

Nick NickKeymaster

NickKeymasterHi Doug

Definitely no silicon!

And I would not use Sikaflex 291. This sets like a glue. People use it to seal keel frames to the boxes and keel bolt covers. Mistake – you try and get these items off in a year or two if you have used it. The plastic strips are ‘service’ items and you want to get them off in the future easily.Why do they need mastic at all? The brass strips will hold them on. Assuming the timber on which they will sit is well primed and painted, just need something to seal the screw holes. I don’t use anything on Helene.

If you feel you must use mastic then I would strongly recommend a butyl based non-setting muck.

I have had very good results with this from Traditional Boat Supplies.

Or you can get Arbomast at a lot of builders merchants.Hope that helps

Cheers

Nick NickKeymaster

NickKeymasterJonathan

How did it go? Any photos?

Cheers

Nick NickKeymaster

NickKeymasterHi Doug

Good to hear from you. Well done for playing Keels!

I am not sure that I fully understand your question in full. I am also far from expert in keel mechanism maintenance – I hope that one of our Keel Gurus will respond….From my experience, if you have removed the keels now is an excellent time to service the pressure plates. You can do a certain amount in terms of inspection and greasing with the plates still hanging on the two (upper) clamping bolts, particularly if you have removed the keelbox cappings in the main cabin forward of the main bulkhead. The plates should be easy to move. If they are badly corroded you may want to drop them out for cleaning up by removing the two upper bolts. They are relatively easy to align for bolt replacement by supporting them from above.

Does that make sense?

Nick NickKeymaster

NickKeymasterHi – many apologies for the confusing signposting on the Forum. There is a stray ‘scroll down to start a new post’ message at the top of the screens to view a topic or a reply to a topic. I will fix this and make the different forum functions easier to use but it will take a few days as it is not simple (for me).

In the meantime, to answer your question:

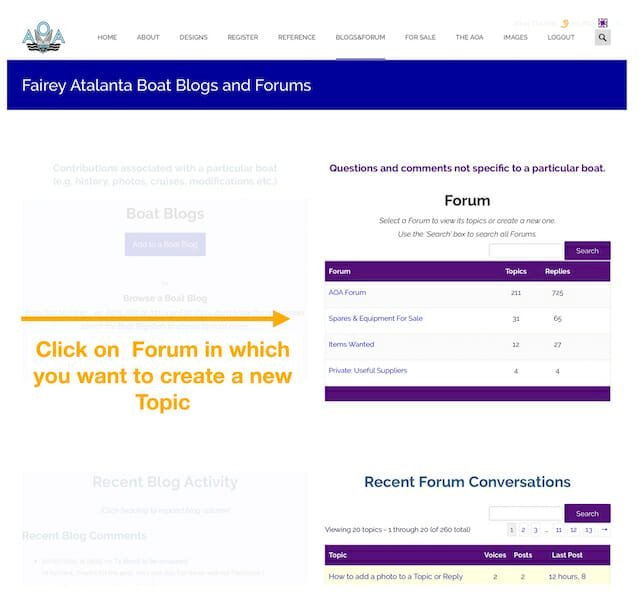

To start a new topic first navigate to the Forum where you want to create a topic:

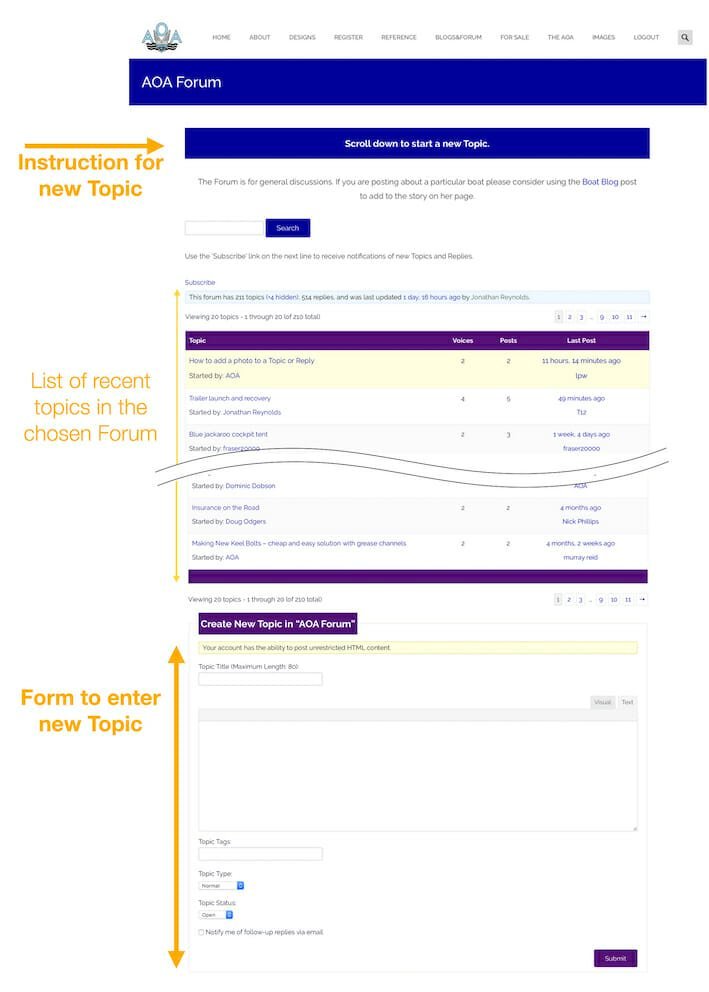

Having ‘clicked on’ your chosen forum title you will see the list of recent topics and there will be a valid ‘Scroll Down. to create a new …’ message at the top of the page.

If you scroll down you will find the form to create a new topic.

NickKeymaster

NickKeymasterHi Jonathan. I am no expert but have donee it once with an Atalanta and many times with a Broads yacht. With the fixed supports you need the boat to float off upwards, not try and slide her backwards on the trailer supports. Which means getting the trailer deep and like Chris says you are unlikely to do that with the trailer connected to the car tow hitch.

Ideally a day with no cross wind and no swell, to avoid bumping the boat on corners of supports and so on.

I think that Richard Hall launches this way – his contact details in the year book.Out of interest – where are you launching? The start of another family summer afloat?

Cheers, Nick NickKeymaster

NickKeymasterHi Fraser

I don’t think there is a standard tent arrangement (if there ever was it has got lost in the mists of time).

I have a very ‘heath-robinson’ affair on Helene (one of the jobs that never got to the top of the list!)

Have you seen the posts about Hiran’s tent here and Chris Green’s excellent tent on A169 Elle here?They often make use of the boom sitting on the mainsheet horse in its raised position.

Have you got any photos of your cover ?Cheers

Nick NickKeymaster

NickKeymasterRory – great to see you online. And even greater to find another potential Atalanta custodian.

I would echo Dom’s comments about what state of boat to buy.

Going to one already in sailing condition will save you a lot of money, and time.

However, there is great reward and satisfaction in renovation – just be realistic about time and cost. And don’t seek perfection – do the things you have to do to get sailing, then go sailing and finish her off around using her. This is the approach George has taken with T12.A55 does look like she may be a viable project but it is difficult to say without either a more informed seller and/or visit (difficult in the current climate!).

As to keeping her dry. It is possible with carefully applie and heavy duty tarpaulin to keep an Atalanta outside but it is very inconvenient for working on them and perhaps only really sensible once renovated and in regular Summer use. For the work I did on Helene I made a ‘tent’ out of scaffold and lorry curtain side canvas ( which survived 7 years, I am embarassed to say). Check out this Topic for more details on people’s approaches. I particularly like A17’s tent which can be easily stored.

Cheers

Nick NickKeymaster

NickKeymasterAnd it really was a class of Motoboats. Apparently A84, Desiree, was also sold to a Thames boatyard and completed as a twin-screw motor yacht.

NickKeymaster

NickKeymasterE-WOW: 1600 Saturday 16th May – Farewell Windemere

This will be a post wrapping up the day. Something like

We very much hope that everyone enjoyed the first Virtual AOA Meet-Up. A number of us particularly enjoyed Nick Rogers taking us through the Windemere Jetty’s Swallows and Amazons exhibition. To counter this I know that there were some that thought ‘a few tatty old books’ didn’t belong in an Atalanta meeting. But overall I think everyone enjoyed learning about the Museum and its exhibits.

The ‘Virtual Meeting Room’ worked much better that many had feared. Technology is always a worry for many of us and although one or two had difficulties the Meet Up seemed to work alright.

It was particularly rewarding that the E-WOW became an international meeting with David and Michelle joining the England and Scotland Atalanta folk from the Virgin Islands. The call including a guided tour of their mountain top home and the views across the Caribbean from their windows which lifted everyone’s spirits!

The final Roll Call for involvement in E-WOW (in Atalanta sail number order!):

Mike Dixon – A1 Atalanta

Bernard Marshall – A86 Sassi

Richard James – A89 Colchide

Doug Odgers – A90 Jenaka II

Dominic Dobson (ex-A90)

Alistair Rodger – A102 Atalanta Mary

John and Marianna Ingleby – (ex-A105 Taku Maru)

Nick Phillips – A124 Helene

David & Michelle Walworth – A146 Le Bateau Ivre

Jonathan Stearn – A183 Bluster

Thanks to everyone who took part. We look forward to being able to return to physical meetings although we now have another ‘arrow in our quiver’ for keeping in touch.

NickKeymaster

NickKeymasterE-WOW: 1235 Saturday 16th May – Yacht Club Bar Now Open

We very much hope that you have enjoyed learning about the Museum and some of its exhibits as part of our virtual Windermere meet up ‘Wild on Windermere’.

With some trepidation we are now going to attempt a technical trick equivalent to working with animals or children on TV.

Click Here to refresh the Windermere thread and see latest contributions below NickKeymaster

NickKeymasterE-WOW: 1230 Saturday 16th May – Windermere Jetty Swallows and Amazons Exhibition

Nick Rogers, a curator at the Museum has very kindly offered us a personal tour of their exhibition celebrating 90 years since Arthur Ransom wrote Swallows and Amazons. I hope that you enjoy it.

Maybe see you afterwards for a quick catch up. I will post a link to the ‘Virtual Conference Room’ in a few minutes – just click the ‘Refresh’ message below.

Nick

Click Here to refresh the Windermere thread and see latest contributions

NickKeymaster

NickKeymasterDavid – great to have you ‘on board’ all the way from Caribbean. Likewise I have never been to the Caribbean which likewise looks lovely. Maybe lovelier….

The weather over here is a bit indifferent – I hope you are basking in sunshine and ideal sailing winds.

NickKeymaster

NickKeymasterWelcome Doug and Jonathan. Just we three at the moment. Might see you on the steam trip Jonathan. I’m wearing a pink carnation and carrying a copy of ‘Classic Boat’.

NickKeymaster

NickKeymasterE-WOW: 1200 Saturday 16th May – Windermere virtual lunch, catch up and steam-boat trips

Continuing the very first ever Virtual Gathering of the AOA

Well, here I am at the Windemere Jetty Boat Museum. The cafe has amazing views over the lake and the food is – well, out of this world!

I had a great sail down from Low Wray. The perfect F4 Easterly meant a fast passage and made it easy to impress the crowds coming alongside on the museum jetty. There was only one other boat on the jetty. Although it was a motor boat I was rather taken with the varnish which looked like a sheet of glass moulded around the wood. Perfect! Almost too perfect, like a dream.

Anyway, anyone else around?

At 1230 the Museum have very kindly offered us a personal tour of their exhibition celebrating 90 years since Arthur Ransom wrote Swallows and Amazons in the Lake District. A ‘Reply’ will be added to this Topic thread to allow you to join in.

And at 1245 a further ‘Reply’ will invite you to join other logged-in Atalanta folk in a ‘Virtual Meeting Room’.

Before that why not take a trip on a steam launch, or learn about the museum and how it came into being. Use the selection of videos below.

Steam launch trip

Some very kind people have offered to take us out on the Lake during our Virtual gathering.

Choose a trip below, or take them all!Learn about the Museum, its building and its volunteers

Aerial footage shot during construction (1m 30s)

2017 Kids project Esperance, they make a video about getting the museum ready (3m 41s)

Facebook announcement March 2019 (about 1m)

https://www.facebook.com/TimBackshallITV/videos/windermere-jetty-museum/307624183233795/

Prince Charles opens the museum in 2019 April from the museum website (clicks through to Museum website)

https://windermerejetty.org/aboutus/windermere-jetty-official-opening-8-april-2019/

The Steamboat museum (Windemere Jetty fore-runner) in 2011 incl Osprey under restoration (about 5m)

And you might find these other links interesting.

- The Windemere Jetty boat collection

- Information about the museum building design:

Click Here to refresh the Windermere thread and see latest contributions

‘See you’ later at the Curator led tour of the Swallows and Amazons exhibition

NickKeymaster

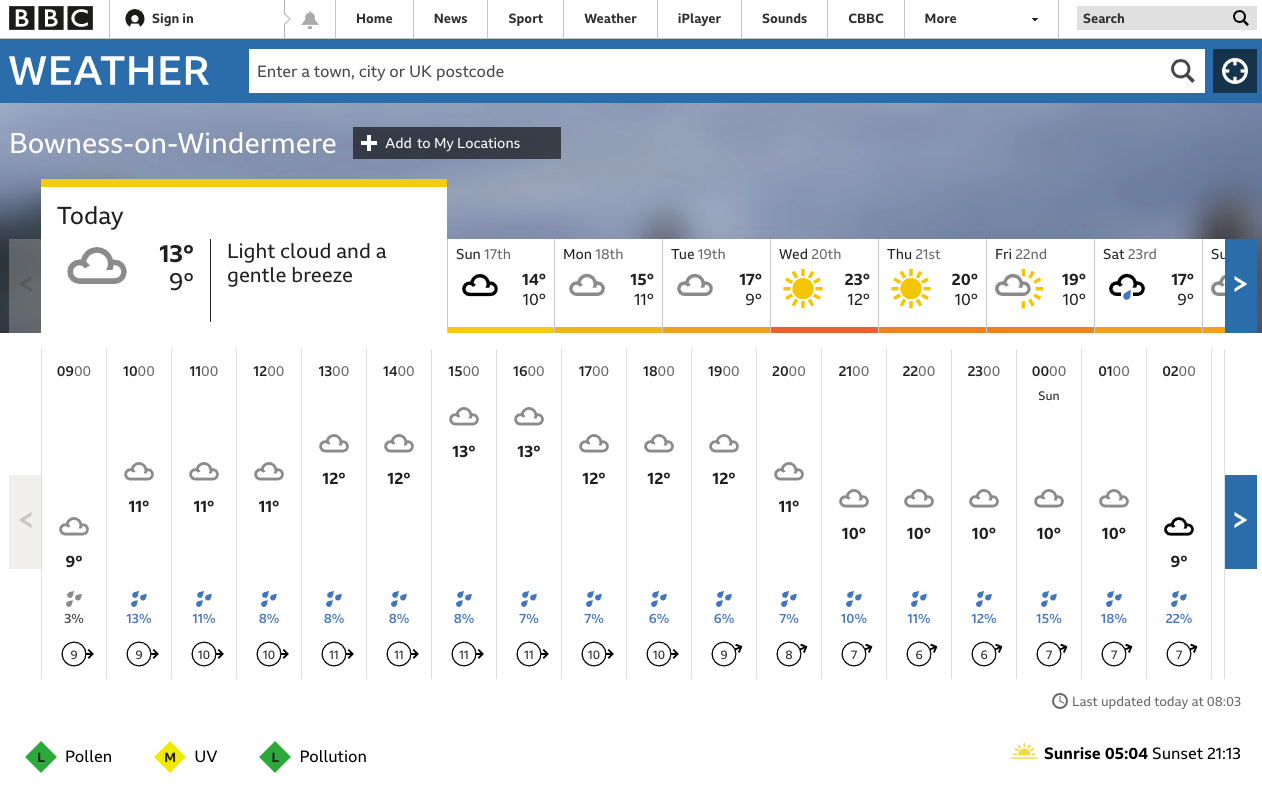

NickKeymasterE-WOW 0900 Saturday 16th May – Windermere forecast for Today

Hi there ….. looking forward to our virtual gathering at the Windermere Jetty Museum later today.

Just checked the forecast for today – dry and not much sun or wind.

See for yourself using one of the Windemere webcams:

- Windemere Lake Cruisers at Ambleside

- Car Ferry webcam at Freshwater Biological Association, looking towards Bowness

Click Here to refresh the Windermere thread and see latest contributions below

NickKeymaster

NickKeymasterFraser – really sorry about your posts which I hadn’t ‘approved’. I don’t normally have to do this for registered users so not sure what is going on (don’t want to undermine confidence in the Webmaster, but I don’t!).

Now done and will look out for any more until I get the issue fixed

NickKeymaster

NickKeymasterBattens and string?

NickKeymaster

NickKeymasterHi everyone.

As with so much in life just now, Wild on Windemere has been cancelled due to the Covid-19 outbreak. See Mike’s post on the home page.

We very much hope (with little confidence) that we may be able to run our other events later in the year but the risks are too high too contemplate visiting Windemere in May.I hope that everyone is coping with the extreme circumstance in which we all find ourselves.

Keep safe!

Cheers

Nick…. embryonic thought, what about a virtual cruise in company later instead …..

NickKeymaster

NickKeymasterA35 is truly an excellent communications link!

We were fascinated to delve into her story when George Caisse, who owned her between 1959 and 1964, contacted us to ask of her whereabouts (top of this thread). And now Bernard Blavier has been in contact to the same end.

Bernard is the man who renamed A35 to ‘Scherzo’ and provided her to the Maritime Museum in Bordeaux back in 1993. In discussion he has given us further insight into her life and some great photos now on A35’s boat page, including this one of him sailing her.

Bernard’s contact has reinvigorated the search for what happened to A35 when the Bordeaux Museum closed down. He is carrying out his own investigations and Mark Urry (of A1 fame) is also on the case. Interestingly a local businessman, Norbert Fradin, is starting a new museum – Musee Mer Marine – and he apparently bought a lot of the old museum’s exhibits. We hope that he may have insight into the fate of A35.

…. the story continues

NickKeymaster

NickKeymasterHi Stephan

To some extent this is a personal choice driven by how you plan to use the boat- there are those that like lots of horses to cope with driving through significant waves and headwinds for hours on end, and others who use engines just to get on and off moorings. Is your 5 knots in flat water or in waves?

Through the years Atalantas have had pretty much every small engine you can think of. Popular choices have been the 9-10hp single Yanmar 1GM and the Beta twin 14hp. Both are higher than the Coventry Victor 12 or 16hp engines usually fitted when new, requiring raised floorboards. Note that petrol engine and modern diesel engine horsepowers are not directly comparable.

I have a 1GM in Helene. I have found it great for my purposes and find it happy to push the boat along at 4-5knots for hours on end even in a chop. Easy to service, smallish, However I have also been very impressed sailing (motoring) on Atalanta Mary with her 14hp Beta.

Another factor to consider in fitting an engine is access to the service points including seawater pump, filters, drain plugs, lift pump and bleed screws and so on.

Not sure if any of that helps….

Cheers

Nick NickKeymaster

NickKeymasterPicking up on Mike’s reference to Atalanta Mary in the previous post….

Alistair’s adventures were written up in PBO May 2014 in an article called ‘South Coast to Sardinia’.

You will also find an extensive blog by Alistair for his canal journey and subsequent Mediterranean sailing on A102’s Boat Page.

Alistair would be worth contacting to get his take on the adventure.Have you tried using the interactive Archive Index on the website yet? If you enter ‘T10’ in the ‘Search’ field you will be able to access write ups from Trevor in various bulletins about his experience with Calista in the UK and Med. A rich vein of experience. (You can also search the index on keywords, subjects, document types etc). Note – the interactive index and access to the articles is a restricted function of the website for Association members only.

Cheers

Nick NickKeymaster

NickKeymasterHi Fraser

I think you could easily use other veneers for the repairs. I have a whole 14′ dinghy cold moulded in mahogany veneer. But not all mahoganies are equal and agba has particularly good rot resistance.

You can help the mahogany by using a saturating epoxy first (eg eposeal) and/or plenty of thinned and then unthinned primer.

I guess there might be potential for issues from the existing agba and new mahogany reacting differently to heat/getting wet etc, but i would think this a low risk.Be interesting to hear from anyone who has used mahogany.

Cheers

Nick NickKeymaster

NickKeymasterStephan

It sounds like a great adventure – both sorting the boat and then the voyage.

There are people who will have a lot of insight into your ideas based on their own similar voyages. A102 Atalanta Mary travelled through the Canals and had a period sailing around Corsica, Sardnia and the Italian and French coasts. T10 has travelled extensively in the Adriatic (as the base for the authors of the Imray Adriatic Pilot). A105 is being prepared for a similar trip. I will leave them to give you their ideas (or you might want to chase them up through the Association Yearbook).

My comments are less about the requirements of the canals and the Med, more about the boat.

I am not a fan of loading Atalantas up with every modern ‘convenience’ you might expect in a modern cruising yacht. The Atalantas were designed as light-weight but very sea-worthy cruising yachts. Adding weight detracts from both the aesthetic appeal of the boats (subjective) and the way they perform. Every additional kilogramme should be challenged as to why you really need it.

That said, some personal opinion specifics:

- Holding tanks – check the T10 boat page to locate Trevor’s articles on fitting a tank to Calista. Atalanta Mary did not have a tank.

- Bimini – Again T10 Calista has a smart arrangement. The height of the Atalanta boom (Calistsa is a Titania) may limit options whilst sailing. Reducing the sail area by raising the boom, particularly in the Med, may not be the best option. Of course you could lengthen the mast raising the whole sail-plan ……..

- Bowsprit – a lightweight affair for Code 0/1 great idea (see Technical Paper P)

- Solar Panels – see experience from A105 Atalanta Mary and A169 Elle. There are some great flexible panels out there that can be included as part of the bimini, sailcover, hatchcover or similar without a heavy structure to support them

- Electric Windlass. Personally not convinced this is necessary based on my reading of other’s experiences. It would have to be deemed essential in my view to justify the weight and complexity (deck reinforcing, electrical system).

- Boom roller -reefing. Handling from the cockpit does not require this. A14 Helene has slab-reefing and the main is easily raised, lowered and reefed single-handed from the cockpit (see 2017-18 Bulletin). Adding lazy jacks would make it even better. And the slab-reefing gives a better shape than roller-reefing.

- Dinghy storage on the sterndeck. The wrong place for weight. Some boats carried their Dinky there but its a lot of faff! Particularly for the Mark 2 Atalantas which have a slightly shorter stern deck than say Dervorguila. The Seahopper idea has been taken up by A169 Elle (see her boat page). Personally I love a hard dinghy but I would either accept towing it (which I do in the UK) or a Seahopper / folding canoe / inflatable.

- Auxiliary motor. Why not electric? Depends on your sailing / motoring habits but some great options out there.

Lots of options, lots of opinions, lots of compromise required. That’s boats and sailing!

Cheers

Nick

NickKeymaster

NickKeymasterHi Stephan

Assessing an Atalanta is, as for any wooden boat, a mixture of taking time, questioning (e.g. ‘where did the water come from to make that soft’) and understanding typical issues for that boat.

You may have found Technical Paper O, drafted a long time ago, dealing with this subject. We are in fact in the midst of an update to it. A professional assessment could be useful but will be costly and you might be better leaning on some friendly Atalanta owners locally. There are at least a couple on the South Coast with extensive restoration experience who may be able to help. Contact the Secretary Richard James for details.

Here are some random personal thoughts on potential Atalanta specific woes, put up for others to augment / disagree with as they see fit. Not a complete list (see the paper) but things that I have personally come across.

The below is not intended to put you off. Atalantas are tougher than perhaps they look and few of the jobs are beyond the average boatowner. There is plenty of experience in the Association to assist with remedies.

I hope this helps. Feedback on this thread will be very useful as part of our updating Paper O

Cheers Nick

——————————————

Before reading it is also worth noting that most of the areas of concern really apply only to boats which have been ‘let go’ and boats don’t generally suffer from them all. Keeping on top of maintenance, a good set of covers (or a barn) and a watchful eye mean that most of these can be avoided or at least dealt with in the early stages before they become a big deal.

Top Sides and hull. Generally resistant to issues unless fresh water has lain inside for long periods. External issues include ‘screw-sickness’ where brass screws have de-zincified visible as screwhead size circles; impact damage visible as cracks in the veneers. Tapping the hull with your finger can help identify (rare) hull delaminations – affected areas sound ‘hollow’ or ‘click’ compared to sound areas. Inside look for high-tide marks, signs of delamination and softness beside the ‘hog’ and uphill sides of stringers, paint which appears to be ‘mottled’. Check the bottoms of bulkheads for softness.

Check the skeg fastenings. It should not move significantly when gently pushed side to side.

Check the stem looking for signs of delamination (it is laminated) and separation between the veneers and the stem.

The centreline as originally built has also lead to issues as the boats age, requiring removal and replacement of the outer ‘sand-keel’. Look for separation between the ‘sand-keel’ woodwork and hull along the centreline. Paper T outlines remedy.

Cockpits. Often deteriorate due to fresh water again. Check all framing etc which should be easily accessed via the ‘tunnels’ from the aft cabin and galley/chart table. Bear in mind that the keelboxes form part of the cockpit structure.

Keelbox Woodwork. Early boats had solid wood sides but most of us have plywood (of good quality originally). Check for ply delamination on every surface you can access and for scoring from the keel mechanism at the forward end. Ideally do this from above by removing the tops of the keelboxes in the galley/chart table area. The screws are generally obvious but the wood may be hard to lift if it has been stuck with sikaflex or similar in the past. The near vertical sloping panels on the aft sides of the keel hoist woodwork will need removing first. You can also inspect from below and from in the cockpit. For the latter check in particular the rear end of the cases. (Paper T includes information about fixes)

Check also the join between the vertical side panels enclosing the lifting gear and the top of the keel cases. These joins are in effect under-water to leeward when sailing! The brass screws holding them together have been known to fail.

Decks. In my experience with Atalantas one of the biggest issues. The sun, movement of feet, and all of the water traps and through-deck fittings lead quickly to water ingress and weakness if not cared for. Tell tale signs of issues are paint flakes in line with the diagonal joins between the top laminate strips, paint flaking /signs of delamination on the quadrant between blister and deck, cracks / lines down the centre of the blister, areas of filler visible on deck. Vulnerable areas are the aft deck, particularly the last 12″ or so and the join over the bulkhead at the rear of the cockpit, the fore- and side-decks on the up-hill sides of the fore-and-aft deck strips, around any through-deck fittings and the hull-blister join. The ‘tapping finger’ can help identify areas of concern. Less easy to examine is the wood underneath cleats, bits and bow-roller – look for rusty water runs underneath inside as signs of trouble.

Fixing all of these is relatively simple but time consuming. A common part of the fix is to glue ‘doubling’ ply to the underside as in Technical Paper S – it really stiffens the whole thing up.

Transom. Check the upper 10″ inside and out. The rear edge of the deck often has a trim which can trap water. Note that the transom is made in two parts with a join in line with the rubbing strakes.

Keel mechanism and steelwork. This is a subject covered extensively in Technical Papers C,F and X and in the Bulletins. A proper assessment requires an understanding of how the keel mechanisms work – see Papers C,F and D. In general the mechanisms are robust and trouble free with regular maintenance. Checks will include “Do the keel bolts move?”; “Do the keels move up and down?”; “Are the clamping plates free?”. Slacken the clamping bolts and it should be possible to move the keelbolts sideways by striking the ends (firmly but not too hard). Try to move lower/raise the keels. If they don’t move judicious application of pressure / thumps from a mallet / penetrating oil might help. The fact that they don’t may not be too serious but will require further investigation.

The steelwork can be inspected relatively easily ‘from the outside’ in the boat, particularly if the keel case ‘lids’ in the main cabin are removed. Through the latter it should be possible to guage the condition of the clamping plates and how freely the move. Look for rusty dribble marks from behind the steel plates on the bulkhead / keelboxes. If time and owner permit, remove one of the keelbolts for examination.

Rudder and Tiller. Generally pretty robust and problem free. Rudder blades and stocks are made of a special alloy, which can suffer from corrosion and stress. See Papers E and M. Check Rudder bearings and also the lead of the uphaul / downhaul: check that for signs of the wires damaging the pulleys inside the transom. Check the whipstaff tiller bottom bearing operates smoothly, and also the four steering wire pulleys.

Mast and Boom. For wooden masts check under / around the metalwork for signs of distress: discoloured wood, separation of the varnish. It is not unknown for water to get behind these fittings and rot the spar from the inside out. The spars were made in two halves, glued together vertically. Check that the glue line is intact throughout.

Chainplates. These are subject to stress and movement. Look inside for rust-stains, cracks in the paint. If water is allowed to pentrate due to lack of paint /attention the plates can rust from the inside, looking healthy on the surface. It may help to assess what’s going on by withdrawing one of the bolts and inspecting the inside of the hole.

NickKeymaster

NickKeymasterHi Fraser

A lot of boats have experienced this problem at some point. Indeed my boat A124 has a few similar looking screws.

You are looking at dying brass screws, which have ‘de-zincified’. Fairey Marine used these brass screws through the hull above and below the waterline to fasten the internal framing / stringers. Over the years the salt water gets to the screws and starts to corrode them. The corrosion causes the paint to crack off which is useful as a warning sign.

In many cases he screws become so weak that you are unlikely to be able to unscrew them – the slots and/or heads just break off. The corrosion can also weaken the wood in contact with the screw.I would love to hear how other people deal with their corroded screws as I have not yet found a method I am completely happy with.

I have tried a couple of approaches:

- Drilling out the screw, priming the hole with unthickened epoxy, filling the hole with thickened epoxy, re-drill, new screw and making good

- This has worked in some cases for me.

- The challenge is drilling out the corroded screw without the drill bit diving off the screw and making a large hole beside the screw.

- Using a small hole saw around the screw to the thickness of the hull, breaking up the plug of wood and rotten screw, removing the outer layer of veneer around the hole to permit a ‘patch’ of veneer to be glued over thickened expoxy in the hole.

- Takes more time

- Involves removing more of the hull material, although the epoxy does have clean timber to bond to

Some people have, I believe, removed the corroded screw and filled the hole and then applied a new screw in a new hole near to the old screw.

Your question has made me think that we should have a ‘technical paper’ on this topic once we have collated everyone’s responses to your question 😉

Nick

NickKeymaster

NickKeymasterSimon

3D Printer engraving sounds interesting!

The dimensions of the plate for A124 are:112mm x 38mm

or, in Atalanta speak, 4.4″x1.5″

Cheers

Nick NickKeymaster

NickKeymasterLooks like a great choice of campsite. Close to a lot of the mast up/mast down action. (For those that haven’t seen it, check out racing yacht ‘Raisena’ going through Potter Heigham with her 60′ mast here).

Apologies, even though I live on the doorstep I won’t be able to make it. I have an appointment with some salty water in Scotland (excited!).

Hope you have a great weekend.

Cheers

Nick NickKeymaster

NickKeymasterHi Fraser

I am sorry to hear that Blue Jackaroo has deteriorated to this extent. The deck problems you describe typically arise from the boat being stored uncovered through the winter.The good news is that people have been here before. I am sorry that the site has not been easier to navigate – I recognise that the search facilities are not necessarily as intuitive as they might be. Something I am working on but rather slowly. I use the ‘Interactive Index’ available on the Archive page, and the general site search option (top right ‘looking glass’). You will need to try a few searches as different people tag items differently – try ‘repair’, ‘deck’, ‘laminating’, and so on.

With regards to laminating the repair the following may be helpful:

- Annual Bulletins here

- 2008-9 page 16

- 2009-10 page 3

- 2010-11 page 44

- 2012-13 page 16

- Mike Dixon’s recent post about his laminating on A1

- There is also a Fairey drawing showing how to do repairs but shockingly I could not find it on the website. I will get it added and send to you.

- As far as possible you should try to match the thickness of your repair veneers to the existing sound veneers – I suspect nearer the 2mm thant 3mm on the decks?

For stiffening up the decks you can try Paper S from the Technical papers, accessible here. I have personally done this ‘doubling up’ on Helene and it has been extremely successful. I don’t think you will necessarily need additional ribs if you double up the decks from below.

I hope the above helps. Good luck with the repairs and let us know how you get on.

Cheers

Nick - AuthorReplies

.

.